Home page » Representation » Press technic

Using the AC servo motor, our electric press shapes the workpiece using a mechanism that converts the rotational motion to vertical.

Pneumatic and hydraulic presses are used worldwide. Our electric press is not a pneumatic or hydraulic press, but our original product.

The press is able to control the pressing force, the final position, the pressing speed, the stopping time, etc.

Special product

We are proud to present this special product in addition to our standard models.

Clean Press: For use in a clean production hall

Short stroke press: With connectors on the side of the compact body

Products suitable for various production lines

We offer three types of Electric Presses to meet different requirements. One is for the production cell type production method (standalone model). Other types can be integrated into a production line and connected to other external equipment. (Master model and unit model).

Our models can be used in the range from 50 kg to 8000 kg

Countless pressing modes

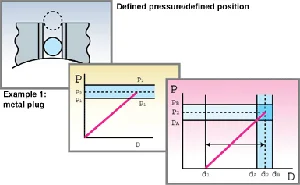

The Electric Press can only be operated using the appropriate units. The Electric Press is a constant speed adjustable end position, end load, or end position function

(etc., see details) can meet appropriate requirements.

Evaluation function / PC Software (Complies with ISO9000 standard)

The Evaluation window for pressure and displacement can be adjusted according to the user’s needs. This allows you to avoid the formation of a non-compliant product and send it to the next operation. (and detection only there) In addition, it can be connected to a PC in order to record and analyze the operation data.

World leader in this field! Can be used for clean production hall installations. (Class 10)

Precision air-tight construction. There are two easy-to-connect air outlet connectors to choose from. Special clean room, electrically conductive paint applied to external surfaces.

The covered bear is lubricated with a special low-evaporation grease.

The press cylinder is made of a special material to avoid static electricity charging.

It can also be used in a clean production hall and in general environmental conditions.

In accordance with FEDERAL STANDARD 209D, Purity Class 10 is defined as follows:

The compact body can be attached to small workpieces (such as semiconductor materials) with a connector on the side. Compact body with side connector: suitable for small work pieces (such as semiconductor related materials) and various equipment. New Edition JPU-S1003 Electric Press Even simpler, even more precise pressing

Bore Seals with Expandable Metal Balls (e.g., Anti-lock Brake Systems in the Automotive Industry) After the Electric Press has detected the top of the metal ball, push it into the hole to the specified depth.

The exact pressure value can be recorded or plotted to ensure the quality of the impression.

| d1: | Detection position |

| d1-d2: | Pressing |

| dA-dB: | Evaluation range |

| pa-pb: | Evaluation load |

First, the bottom plate is pressed onto the shaft in the specified position. The roller is then placed on the shaft and the lower plane of the upper plate is pressed at a precisely defined distance from the upper plane of the lower plate. Because the plate is pressed with a precisely set load, the durability of the structure will be adequate.

The Electric Press is also capable of providing constant pressure for a period of time specified by the user, ensuring that the materials bond to each other with adequate strength. Can also be used in connection with ultrasonic welding.

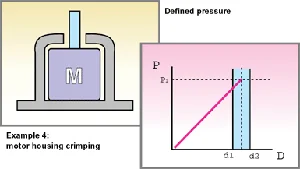

The edge of the aluminum housing can be bent to secure the position of the motor. The pressure can be precisely controlled so as not to damage the engine.

If you would like to connect our robots to your equipment, please contact us!

Together with the “JPE TaS System” software. It has four applications.

PC can be connected to the Electric Press for easy and convenient operations. The data can also be loaded into an Excel worksheet, displayed as desired, or printed out. Assistance with product liability and according to ISO 9000.

Combining many years of technological and manufacturing experience, we have developed a new member of the JPE family of the AC Servo Electric Press to achieve high performance. The new Electric Press uses the AC Servo motor to achieve its extreme positioning ability. The electric press Unit model is used for in-line installation in combination with external equipment. A simple teaching method via PC software allows for easy setup and allows you to solve significant tasks. 31 variables can be controlled via the RS-485 controller.

PC software for the Electric Press

Together with the “JPE TaS System” software. It has four applications.

The “JPETT” application is used to create teaching data on the PC and transfer it to the Electric Press for the appropriate operation. The Electric Press can also be controlled from an external unit after setting the teaching data on the PC.

The “JPEDS” software is used to read the operation data, such as the bear displacement position, the detected load, the elapsed time, and to send them to the PC and display the data on the PC screen.

“JPEQC” software can be used to evaluate product quality, such as product variance, process capability. The software uses the data collected by “JPEDS”.

The “JPEMT” software is used for maintenance and has the following functions: “I / O Monitor”, “Current Status Monitor”, “Command Monitor”, “Load Calibration”, “Sensor Setup”, and “Diagnosis”.

Official website of JANOME: www.janomeie.com

The Flexmont Kft / Ltd. has been dealing with assembly automation (assembly technology, automation), custom machine manufacturing, and specialized machine construction since 1974. The activity was based on the purchase of several Western European licenses. The licenses included the right to market ergonomic workplaces, conveyor systems, small assembly machines, vibratory feeders, manipulators, presses, and building components.