3D printing

Flexmont Ltd. offers two types of additive technologies to its customers, glass fiber reinforced plastic 3D printing and micro carbon reinforced plastic 3D printing. We undertake printing at a favorable price, even based on a unique idea. With a fast turnaround time, you can have your finished product in your hands within hours.

Ultimaker S5 3D printer

The Ultimaker S5 3D printer provides a comprehensive 3D printing solution for industry with its dual-head design, large build area, outstanding accuracy, reliability and ease of use.

Applicable manufacturing materials

Tough PLA, Nylon, PLA, ABS, CPE, PVA, PC, TPU 95A, PP and breakaway support, composite materials

Printing volume

330 x 240 x 300 mm

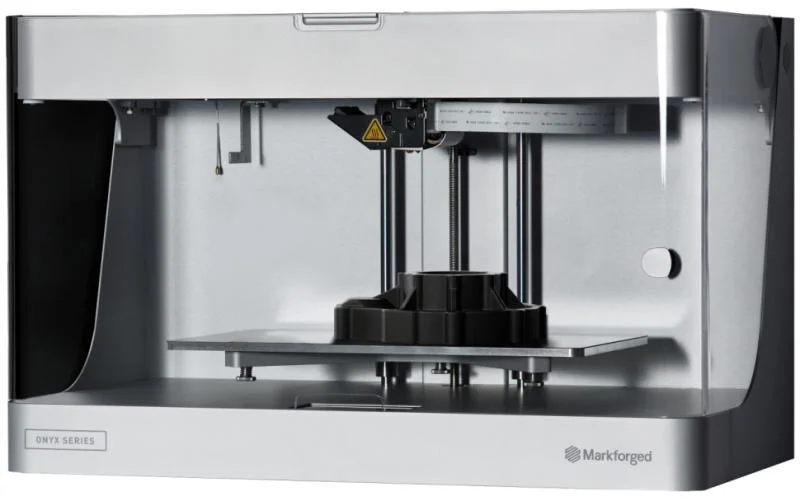

Markforged Onyx PRO 3D printer

Markforged's unique continuous filament reinforcement capability technology can replace aluminum, PEEK or POM parts previously made by milling. The Onyx Pro dual-head composite 3D printer prints Onyx material with its primary print head, into which the second extruder is able to embed continuous glass fiber reinforcement. This creates extremely resistant, industrial-strength parts and end products.

Printing technology

FDM/FFF + CFF, plastic fiber melting + continuous fiber reinforcement

Printing volume

320 x 132 x 154 mm

Printing chamber

closed, tempered

Print head

- 2 print heads, one prints the matrix material and the other prints continuous fiber reinforcement.

- Raw material jam and run-out sensor.

Layer resolution

100-200 microns

XYZ positioning accuracy

6.25, 6.25, 10 microns