Custom equipment

Vibrating conveyors and sorting units, vibrating feeders

Custom equipment designed by the engineers of Flexmont Ltd. is the basic element of machine manufacturing. Vibrating conveyors and sorting units, better known as vibrating feeders, are machines for feeding various standard, bulk products in an ordered form.

Circular vibratory feeder

Circular vibratory feeders are basic building blocks with a stable construction, the task of which is to arrange and continuously transport bulk components.

- Stable construction.

- Electromagnetic drive.

- Fiberglass reinforced or steel leaf springs.

- Drive size range: ø130-550mm.

- Vibrating plate material: stainless steel, aluminium, industrial plasticl, ipari műanyag

- Shape: cylindrical, conical, stepped.

- Noise-damping plastic coating on the outer plate surface.

- Wear-resistant two-component inner coating on the inner plate surface.

- Brush coating for oily, dirty parts.

Linear vibratory feeder

The linear vibratory feeders are installed between the circular vibratory feeder and the pick-up positions. Their task is to buffer the sorted parts and ensure cycle-independent service.

- Proportional design, with small space requirements.

- Electromagnetic drive.

- Fiberglass-reinforced or steel leaf springs.

- Different construction sizes.

- Bridging length up to 800 mm.

- Adjustable high transport speed.

Refillers for vibration conveying and sorting units

Vibrating trough refiller

- Serves for intermittent filling of vibrating plates.

- Stable design with electromagnetic operation.

- Can also be delivered with a belt drive.

- Tank material stainless steel.

- Tank design adapted to the product.

Push-bar filler

- Serves for intermittent filling of vibrating plates.

- Pneumatic intermittent operation.

- Tank design product-specific.

- Tank material stainless steel.

- Control can be independent or remote-controlled.

- Mainly for feeding parts that cling to each other.

Inclined conveyor

- Multifunctional building element, suitable for refilling circular vibratory feeders and direct sorting service.

- Tank design part-specific.

- Tank stainless steel or painted.

- Conveyor chain or belt.

- Fixed or variable speed.

- Gentle equipment in terms of product handling.

- Control task-specific.

Control

- Soft start, adjustable ramp-up.

- On and off delay / 0-4 sec/.

- Output frequency 25 Hz or 50 Hz.

- Vibration amplitude minimum and maximum limit setting.

- Vibration amplitude control with potentiometer or 0-5V voltage signal.

- Two sensor inputs, for receiving proximity switch or opto gate / PNP/.

- External potential-free or 24V direct start-stop.

- 4 selectable operating modes.

- Can be snapped onto TS35 rail.

Complete solutions

- Technologically advanced vibrating feeder with vibrating rail.

- Vibration feeding with refill.

- Multi-track technologically advanced sorting unit.

- Technologically advanced inclined conveyor equipment.

- Vibration robot cell equipped with processor.

- Automatic cell served with vibration feeder.

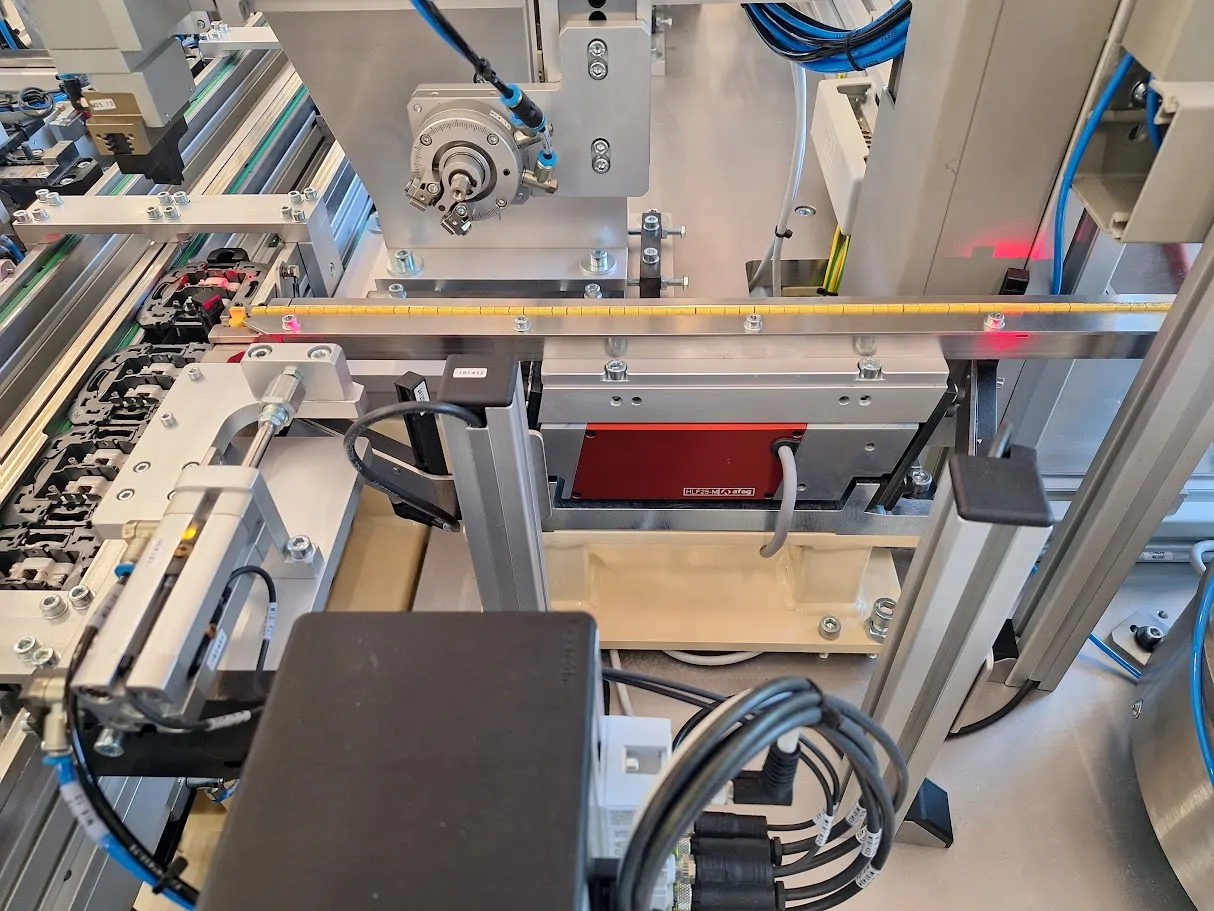

Press technique

The equipment of the position structure can be selected depending on the pressing tasks. The devices providing the pressing force are operated by pneumatic, hydro-pneumatic, hydraulic or electric servo systems. The control can be pneumatic or PLC (computer) controlled. The operation can be started with a foot pedal, two-hand starter, push button, piece position detection, protective window closure, intelligent control panel, etc. as required. The positions can be equipped with an assembly rotary table, a pusher. Force gauges, length gauges, strain gauges can be installed in the positions to measure various physical characteristics.

Other IT options:

- remote diagnostics

- data collection

- repair diagnostics, etc.

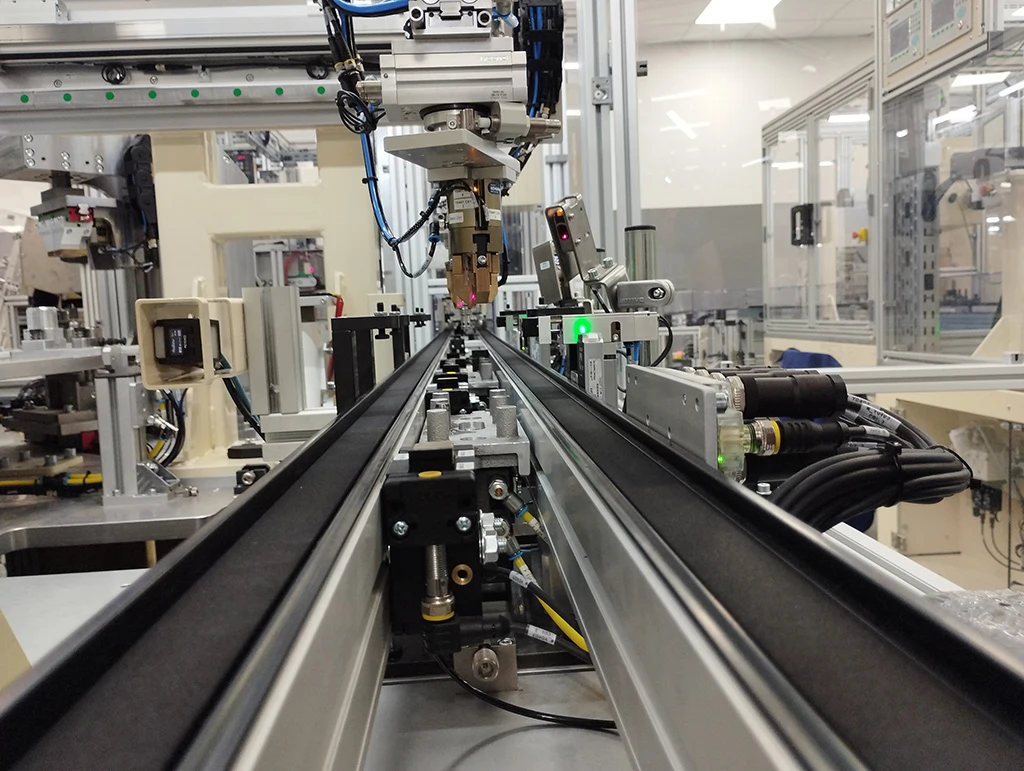

Conveyor systems

Conveyor systems move parts or pallets between two assembly positions. The conveyor can be of full-belt, chain, twin-belt, twin-chain, toothed-belt and roller design. Its arrangement can be horizontal, inclined conveyor broken plane. According to operation, we distinguish between fixed speed, stepless regulation and step mode. The size is adapted to the given task. The conveyor belts can be organized into a system according to technological needs, equipped with their own control. In the case of twin-track systems, the carrier plates can be ordered in a technological design. The frame structure is steel or extruded aluminum. When building conveyor systems, Flexmont Ltd., as a system integrator, primarily uses Rexroth building blocks. For unique, special tasks, it uses its own constructions.

Screwdriving technology

Equipment for performing screwdriving operations in assembly positions. The screwdriving motors are pneumatic, electric, manual or automatic. They can be equipped with torque measurement, length control and automatic screw feeding. They can be single- and multi-spindle designs. If necessary, they can be equipped with camera shape recognition with computer data collection.

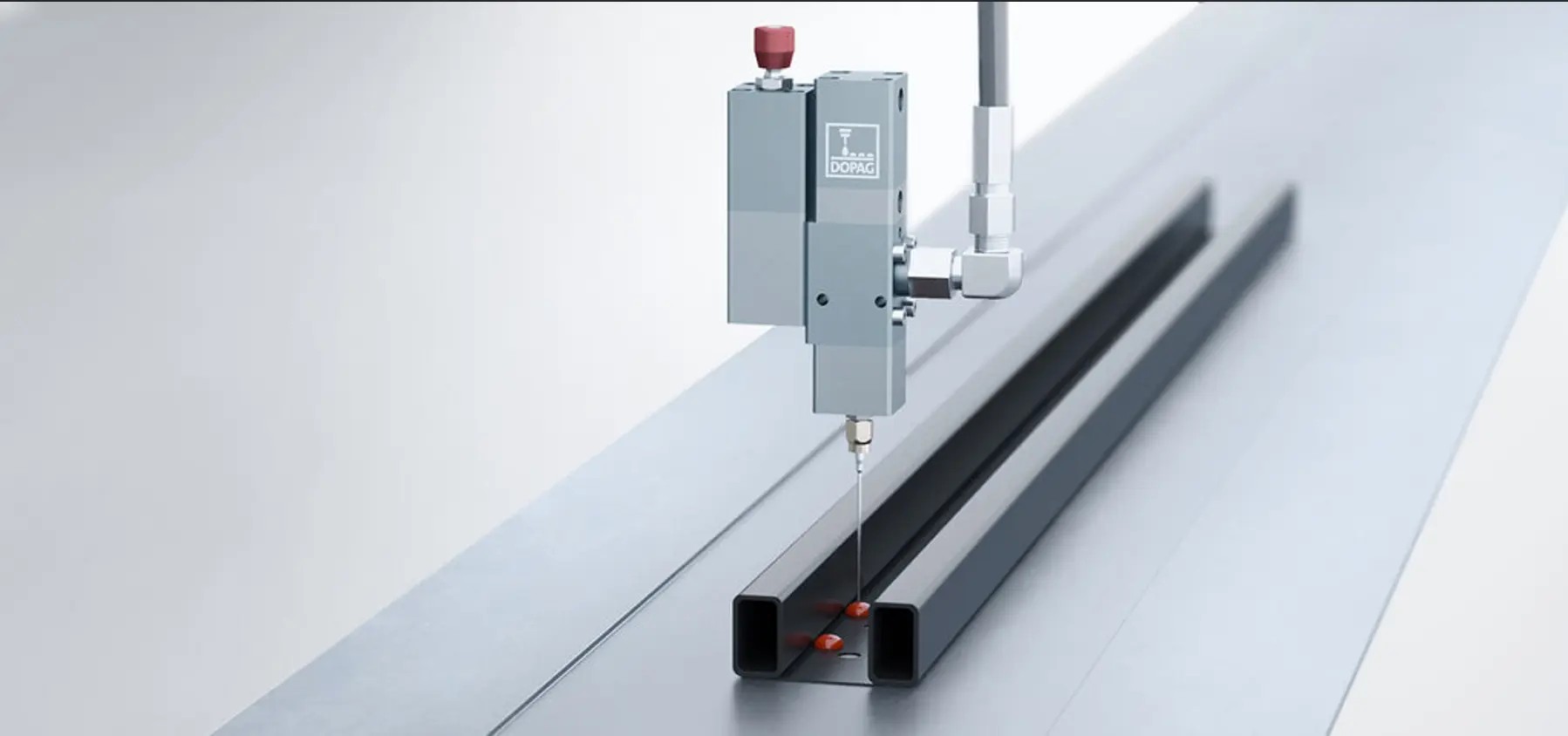

Dosing technology

Grease, glue, silicone, foam, resin occurring in assembly processes. The equipment is used for the precise dosing of one- and two-component mixed materials. The temperature of the dosed products can be room temperature or heated. The basic equipment components are provided by the products of the Hilger u. Kern/DOPAG group, the exclusive representative of which products in Hungary and the CIS countries is Flexmont Ltd.

The additional peripherals required for dosing: workplace and position design, dosing head movement, system integration, commissioning, servicing, spare parts supply are provided by Flexmont Ltd.

You can find more information on the following page:

Wobbling riveting

In those riveting technologies where the shank bends during riveting si is exposed to danger, or the design of the head shape is important, or some inscription needs to be made on the rivet head, the wobbling riveting process is recommended. The equipment has riveting force programmability, a length gauge. The wobbling riveting movement around the rivet shank can be 2D or 3D, single or multi-head design. The basic equipment is provided by the products of Bodmer Küsnach AG, the exclusive representation of which products in Hungary and the CIS countries is provided by Flexmont Ltd.

The additional peripherals of the riveting technology: integration into position, additional automation, commissioning, servicing, spare parts supply are provided by Flexmont Ltd.

You can find more information on the following page:

Robot technique

Assembly robots are well suited for the positioned insertion of components to be assembled in assembly tasks – especially in fast operations, with multiple type changes. These devices can also be used to move the dispensing heads in a spatial path in various dispensing technology solutions. The basic equipment is provided by the Japanese company JANOME.

The robots are technologically developed, programmed; integrated into the system, put into operation and serviced by our company, Flexmont Ltd.

You can find more information on the following page: